And when I say “a few hours” it really is for a few hours. Part of my job description as the Basketmaker’s Wife involves helping…

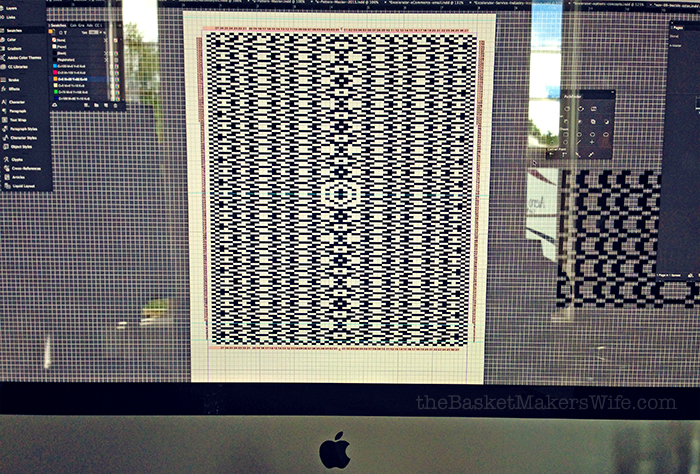

Tag: basket pattern

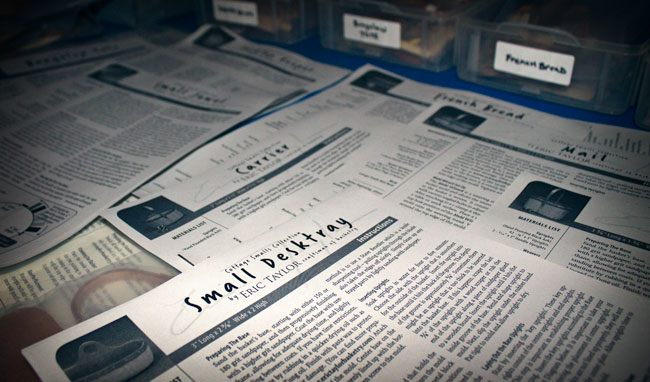

Mr. Basketmaker has been busy in the shop getting ready for his classes in North Carolina. And as he mentioned in his post Saturday that since…

Many of you know, especially if you have taken a workshop from Eric, that his baskets are made on forms or otherwise better known as…